HAZARIBAGH LEATHER INDUSTRY AND SLUMS IN BANGLADESH

INTRODUCTION

Bangladesh has a very limited stock of known mineral resources (only natural gas is being extracted commercially), and the economy is heavily dependent on small-scale agriculture. Agriculture accounts for about 40 per cent of Bangladesh's GDP and about 60 per cent of employment.

Landless small farmers and as well as urban informal groups constitute 50 per cent of Bangladesh's population. Fifty three per cent of rural population are virtually landless and the result of that a very large percentage of urban population live in slums.

For example 30 per cent of the population (about 2 million) in Dhaka live in more than 1500 slums and squatter settlements, where density of settlements is over 6178 persons per hectare and per capita living space available is lower than one square meter. The structural conditions of the shelters are one of the worst in the world. The settlements live without open space, streets, water, gas and electricity, water, sanitation and sewerage facilities.

Since these settlements are illegal the Government or International Aid Agencies have hardly any project to improve living quality of the poorest population of the country. Like many other cities of the developing countries the population of Dhaka city increased by almost 200 per cent in seven years (1974-81) due to the increasing developments of landless peasants.

The present economic development increasingly widens the gap between the poor and the rich. The limited agricultural land does not allow any further expansion along with the fast expanding population of working age. In view of this problem the Government of Bangladesh is planning for a rapid increase in industry, commerce and services (55.7 per cent of GDP). At present industrial manufacturing accounts for about 10 per cent of GDP in Bangladesh and 10 per cent of total employment, and contributes about three-quarters of total merchandise exports. The earliest industries in Bangladesh were based primarily on agricultural products like jute, sugarcane, tobacco, forest raw materials, and hides and skins.

During the mid-sixties a modern industrial base emerged as heavy industries like steel, machine tools, electric machines, diesel plants, refineries, pharmaceutical plants and other chemical industries were set up. From 1985 to 1990 the industrial sector achieved an average annual rate of growth of 4.02 per cent. In recent years, the major source of industrial growth has been in textiles, with ready-made garment manufacture expanding from insignificance in the 1970s to the leading export earner today. Leather tanning and brackish water shrimp farming have also expanded rapidly and are expected to grow further.

With the increase of unplanned and socially and environmentally degraded industries Bangladesh poses a new challenge. Pollution and human-induced hazards are particularly serious in the developing nations, because industrial production is heavily concentrated in one or two city regions or 'core regions' within each nation.

The industrial areas in Bangladesh are situated in the midst of densely populated regions. There are many hazardous and potentially dangerous polluting industries situated in the cities of Bangladesh. In Dhaka at Tejgaon area, food processing industries are situated along with chemical and heavy metal processing industries. In Tongi a pharmaceutical industry is situated near a pesticide producing industry.

Tannery industries of Hazaribagh also situated in a heavily populated residential area. These examples are repeated in the cities of Chittagong, Khulna and other smaller cities of Bangladesh. The Government of Bangladesh has not shown much interest in environmental impact created by the industries, whereas government's concern to create jobs usually meant that when a new factory is proposed - by local, national or international business or agency - little attention is given to the likely environmental impacts.

Tanneries discharge 21,600 square meters of liquid wastes daily

Tanneries in the city's Hazaribagh area discharge some 21,600 square meters of liquid wastes everyday. "These harmful wastes, including chromium, lead, sulphur, ammonium, salt and other materials, are severely polluting the capital city and the river Buriganga," State Minister for Environment and Forest Jafrul Islam Chowdhury said this while he was visiting the Hazaribagh industrial area yesterday.

(UNB, November 2003)Many urban dwellers live on sites prone to hazards - rarely the government tries to help reduce risks or to respond rapidly and effectively, if a disaster happens. Hazardous sites are often occupied illegally; the risk of eviction from such sites is small because of any commercial value or because they are publicly owned and the government shall not force their eviction for political reasons. The outcome of this are:

- Houses are built without providing basic amenities like water and sanitation;

- Slum-lords manipulated the whole show by renting the houses to others and expropriating exorbitant amount of money;

There are many disasters which have an impact which goes far beyond a particular house or neighbourhood, as a result of industrial or other accidents. Bhopal shows an example, when an industrial accident in 1984 released methyl iso-cyanate and caused the death over 3000 with perhaps 100,000 or more seriously injured or poisoned. The situation like Bhopal threatens many places in Bangladesh.

While the most polluted industries are decreasing in the industrial countries a rapid increase in more environmentally degraded industries (without effluent treatments) occurring in the developing countries. The economic development in Bangladesh is producing more landless people and at the same time the landless and jobless poor are gathering in cities slums.A typical example is Hazaribagh leather industry in Dhaka. The leather industry is situated in the midst of a densely populated residential area surrounded by slums, where people are living ignorantly in the one of the worst polluted areas in the world. The condition to describe the living conditions of the slums is beyond authors capability (see Figures). The leather export is growing and at the same time conditions of the poor are deteriorating. A case study of Hazaribagh industrial area is proposed in this paper.

BACKGROUND

Leather sector also produces 150 tons solid waste a day

The leather industry sector, which is the fourth largest foreign exchange earner of the country contributing about six per cent of total export earnings, produces 150 metric tons of solid waste every day contaminating the environment and water of the metropolis.

59 per cent of the total wastage comes from processing of hides and skin, and accumulates in the swamp-sludge, experts in the environment sector said. The experts said, "part of the solid waste is collected by the Dhaka City Corporation (DCC) and taken to landfill sites."

A recent research conducted by Professor S M Imamul Huq, Chairperson of Soil, Water and Environment Department of Dhaka University revealed that out of 214 tanneries in the country, except for two BATA and Dhaka Leather Complex-none of the tanneries has a treatment plant as required by the law.

Rice and wheat were grown in a pot experiment in soils from the tannery area. The wheat showed delayed maturity and stunting growth while rice showed late flowering and maturity with dark green colour. In another experiment it was observed that application of tannery effluents to soils of differing textures resulted in reduction of yield of rice, the research said adding that the adverse effect was more pronounced in light soils than in heavy soils. The effluent was also found to negatively affect performance, nodulation and growth of mung beans (dal).

In his research article named "Critical Environmental Issues Relating to Tanning Industries in Bangladesh," Professor Imamul Huq said, "most of the waste effluents are subjected to natural decomposition in the environment, causing serious pollution problems affecting soil, water, air and human life."

The finding said that the existing industries in most cases do not have any effluent treatment plants for neutralising the toxicity and harmful effects of their pollutants.

The research recommended building of appropriate waste treatment plants for neutralising harmful chemicals before disposal of the waste into the environment and called upon the government to fix a legal limit value for discharge of tannery effluent to surface water.

Stressing the need for treatment methods to combat pollution including segregation of processed waste water, sedimentation, neutralisation and biological treatment, the paper said that about half the tanneries apply some kind of solid waste reuse, while 90 per cent of the finished trimming wastes are used by the local shoemakers.

The research said, "the process of tanning produces both liquid and solid wastes. Solid wastes are from the initial and final stages of processing while the effluents are produced mostly during tanning and dying." The 149 operating tanneries produce 14910 metric tons of effluents or waste water during the peak time, about 9100 metric tons during the off-peak period, the research paper said adding that the effluents contain dissolved lime, hydrogen sulfide, acids, chromium dyes, oils, organic matter and suspended solids.

"The waste water is discharged into open drains and ultimately finds way onto land surface and into natural waters in the vicinity," the research revealed. It says "about 3000 tons of sodium sulfide and nearly 3000 tons of basic chromium sulfate are used each year for leather processing and tanning." The other chemicals used in the tanning industry are non-ionic wetting agents, bactericides, soda ash, calcium oxide, ammonium sulfate, ammonium chloride, enzymes, sodium bisulfate, sodiumchlorite, sodium hypochlorite, sodium chloride, sulfuric acid, formic acid, sodium formate, sodium bicarbonate, vegetable tannins, syntans, resins, polyurethane, dyes, fatemulsions, pigments, binders, waxes, lacquers and formaldehyde.

Out of 214 tanneries, 200 are located near the capital’s river systems – the Turag to north-west, the Buriganga to the south-west and the Sitalakhya to the south-east, with Turag flowing into the Buriganga.

The tanneries discharge the effluents and wastes into the river system causing a large area of acid sludge alongside the flood protection embankment and the liquid wastes are dumped in the river through a flood control regulator-cum-sluice.

During monsoon months, the flood protection embankments protect Dhaka from heavy flooding while making it difficult to flush-out waste water, thereby creating environmental hazard. During the dry season the waste water is flushed out into the river causing pollution of the river water and affecting the aquatic flora and fauna. The dumping of the solid wastes is seriously affecting the soil and plants, besides vitiating the air, groundwater and human health.

The water quality of the river Buriganga during wet season and dry season are heavily polluted so that dissolved oxygen in the river water is found to be nil during the dry season and no fish or other aquatic animals can live in this condition.

(Source: The Independent, May 09, 2006)The annual supply of hides and skins in Bangladesh is estimated to be about 13.95 million square meters. Only 15-18 per cent of the total supply is needed to meet the domestic requirements and the rest about 11.81 million square meters remains surplus for export.

The small leather industry of Indian-subcontinent developed Indian vegetable tanned crust over a hundred years ago to preserve the hide in the safest way to suit Indian conditions. The development of leather processing industry was started in Bangladesh in the late 1940s.

Until mid 1960s, the leather was dominated by vegetable tannage for supply to W. Pakistan, Iran and Turkey. Manufacture of wet blue, the chrome tanned semiprocessed leather started featuring in 1965. There was a rapid growth of tanning industry in Bangladesh during 1970s and by the end of 70s. Until 1980-81, the export from leather sector was almost 100% in the form of wet blue, the chrome tanned semi-processed leather

In 1977 the Government of Bangladesh imposed export duty on wet blue leather so that the industry produces crust and finished leather. With the ban on wet blue export from July, 1990, the leather industry of Bangladesh is entering into second phase of its development, the conversion of finished leather into further value added leather products to earn more foreign exchange. Promotion and Protection Act of 1980 provides protection of foreign investment in Bangladesh. There are German, Italian etc. joint venture plants are established in Bangladesh (M/S H. H. leather Industries Ltd, M/S BATA, M/S Lexco Ltd, M/S Apex Tannery Ltd).

The operation in tanning which give rise effluents may be categorised into pre-tanning and post-tanning processes. Pre-tanning is employed mainly for the removal of impurities from the raw materials. These consist largely of protein (blood, hair, etc.) and the process chemicals employed include salts, lime and sulphides. The tanning processes themselves are used to alter the characteristics of skin or hide and their effluents contain chromium and vegetable or synthetic tanning. Post-tanning process include coloration and produce effluents typical of these addition processes; that is, containing residues of dyestuffs or pigments and larger quantities of auxiliary chemicals.The process chemicals employed are a variety of inorganic and organic materials, affecting total solids, pH, COD and of particular importance are the applicable quantities of sulphide and of heavy metals.

Hazardous chemicals for leather and dyes treatments are Ammonium Bicarbonate, Chromic Acetate, Ethylene Glycol Monoethyl Ether, Methylamine, o-Nitrophenol, Toulene Diamine, 2,4,5-Trichlorphenol, Zinc Hydrosulfite, Zinc Sulfate, tert-Butylamine, Cadmium Nitrate, Cadmium (II) Acetate, Copper(2)Nitrate, 1,4-1,8 Dichloronaphthalene, Nickel Sulfate, o-Xylene, Zinc Nitrate etc. For example Chromic Acetate shows the following characteristics (Sax, 1986):

- Potential for Accumulation: Positive

- Food Chain Contamination Potential: Positive, can be concentrated in food chain.

- Etiologic Potential: Chrome ulcer

- Carciniogenecity: Potential, higher occurrence of lung cancer

- Acute hazard Level: Extremely toxic if ingested or inhaled. Corrosive to living tissue.

- Degree of Hazard to Public Health: Highly toxic material via ingestion or inhalation. Corrosive to skin and mummer; potential carcinogenic.

At present in Bangladesh the tanner's basic wet process technique is to treat the stock with increasing concentrations of process chemicals using water as the carrier. In order to ensure full penetration of the thickest hide or skin in the batch, these concentrations are in excess of what is needed and the unabsorbed chemicals are discharged in the effluent, where they are a waste and cause expensive treatment problems.

While the Chemical companies in the Federal Republic of Germany, the United States, the United Kingdom, Switzerland, Spain and Italy provide short term training on the application of their chemicals, Whereas they do not provide any assistance how to treat toxic effluents that increasingly contaminate surface and ground water. Consultant provide technological transfer and management either on arm's length fee paying basis on assignment or financed by the World Bank, UNIDO, ITC or other United agencies.

The small cottage tanners of Hazaribagh producing sandal leather out of cow heads are probably the only tanning group in the world using waste tanning liquor from the modern tanners as their process liquor. But after using these waste are eventually discharged, as are all other tannery discharges in the Hazaribagh tanning effluents into the streets, gutters and sewers which ultimately enter surface and ground water.

According to Dittfurth and Röhring (1987) about 250 different toxic chemicals and heavy metals like cadmium, chromium, arsenic, zinc etc. are used by the leather industry. When the local industry was basically a vegetable tanning complex, this effluent might have been high in BOD and unpleasant but particularly dangerous.

There is, in addition, an extremely hazardous air pollution occur in Hazaribagh which is not known in any other places of the world. The rest treated hides and skins are cooked in open air to obtain glue for the local market. They burn treated leather pieces instead of coal or wood as it is cheaper. The smog and the smell like a witch cooking pot and it is beyond author's capability to narrate. The most hazard occurs when the poorer group uses poisonous treated leather pieces as an alternative fuel to cook regular meals.No body knows how much harm and potential carcinogen diseases will occur to the slum inhabitants. There is no warning from the Government or aid giving agencies or their representatives. This is the vicious circle that the poorest groups are the worst victims of the foreign currency earning schemes.

We welcome the directives by the High Court to the government on relocation of the tanneries from Hazaribagh area to Savar in eighteen months' time. We were nothing short of happy when the Prime Minister had announced quite a while ago her government's decision to relocate the tannery plants from a densely populated area to a more suitable exclusive zone. But sadly it has so far remained a declaration of intent only and a mere announcement. The agencies concerned have made little headway in relocating the tannery industrie.

Big concerns or influential persons (about 80 per cent of the members of the parliament in Bangladesh are traders ) do not care for environment or existing laws:

Tannery being built defying High Court order

It also asked the government to explain why it should not be directed to shift the industries from the area within 18 months. The new industry is springing up just opposite to the Shikdar Medical College inside the embankment in Hazaribagh. Half of the construction is already complete with the owner dredging out the river and filling up the low land. Nurul Alam is the owner of the new industry named 'Millat Tannery' and he is well aware of the High Court order.

"I know about the order and the government's relocation procedure. But it will take time. So I am investing on this. I will also shift my industry when others will shift theirs," Nurul Alam said. He believes nothing will happen in two to three years, as the government's project regarding relocation of the tannery industry has not been approved as yet at the Executive Committee of the National Economic Council meeting

Meanwhile, the water of Buriganga river has become black and mucky due to continuous inflow of untreated tannery effluents. The tannery units release nearly 22,000 cubic metres of untreated toxic waste everyday to the Buriganga River. According to the local people, the condition of the river is the worst (Daily Star March 25, 2003).Toxic tannery waste posing health risk

Factory relocation stuck in red tape

Buriganga river posing serious threat to human health as relocation of the factories is caught in bureaucratic tangle. Reluctance of the owners to move those flouting High Court orders is also delaying the process.

The HC directives, demands of the civil society and campaigns by the media have all gone in vain as the tannery owners and the government have been blaming each other for not taking action in this regard. In June 2009, the HC expressed frustration over industrial pollution, and observed that the government has not taken any step to prevent pollution by industries.

The court in its judgement ordered the authorities concerned to complete relocation of the leather industry to Savar by February 28, 2010. Failing to do so, the government had filed a petition with the HC seeking two more years for the job.

The HC then extended the time till August 28 the same year asking the industries ministry to submit a report within six months on the actions taken to move those out of the city's residential areas. But the government again failed to do the job and kept on seeking more time from the court every six months.

"We're trying our level best. But I'm not sure when they will be relocated," said Mahbubur Rahman, project director of Savar Leather Estate of Bangladesh Small and Cottage Industries Corporation (BSCIC), who is also responsible for implementing the relocation. Asked why they are taking so much time, he said, "It took nearly one year to complete the technical evaluation of the central effluent treatment plant (ETP) and submit it to the government.

"But surely, things are progressing. We've recommended four ETPs with five million cubic metres of toxic waste treatment facilities for 155 industrial units." The relocation process started nearly 10 years ago following a HC verdict in 2001. The government undertook a project to develop the leather estate at Harinbari in Savar at the cost of Tk 500 more than five years ago. The estate, however, remains unused and empty.

Sources say the relocation is being delayed as the government and the tannery owners could not reach any consensus about compensation and bank loan. Even the project director is unaware about the compensation and loan issues -- two major demands of the tannery owners.

The polluters who earn around Tk 1,600 crore by exporting leather goods remain adamant demanding compensation of Tk 1,090 crore from the government along with soft loan and readymade central ETPs at taxpayers' money. "We're asking Tk 1,090 crore in compensation. But we haven't heard anything from the government yet," said Shahin Ahmed, president of Bangladesh Tanners' Association.

Now the government proposes for sharing the cost of setting up the central ETPs, which will require more than Tk 300 crore. "But we signed a memorandum of understanding in 2003 with the government, and the government agreed to set up ETPs at its cost," said Shahin. He also said they demand the compensation, as they will have to build new infrastructures and repair machinery that will be damaged during relocation.

Although the environmental protection laws require the tanners to set up ETPs in their factories, they never did so causing serious environmental peril.

The residents of the city's western part continue to suffer from adverse effects of pollution caused by tanneries in Hazaribagh, Dhanmondi, Basila, Kamrangirchar and surrounding areas. The dreadful stink of the tanneries can be smelt from miles away in residential areas like Rayerbazar and Zigatola.

Hazaribagh tanneries, an export-oriented cluster of industries, produce some 20,000 cubic metres of toxic waste laden with chromium and at least 30 other toxins every day. The toxic waters flow into the Buriganga through the Rayerbazar sluice gate. Locals allege they frequently require treatment for skin diseases, fever, cough, gastroenteritis, asthma and diabetes.

A tanner said the major obstacle to the relocation is that most of the land and property is mortgaged against bank loans. Until the banks release the mortgaged property, it is impossible to move their factories (P. Roy, May 28, 2011).Poisoning Poultry, Fish Tannery Waste In Feed Allowed For A Decade

Women work to sun-dry solid waste, generated from boiling of tanned leather off-cuts and shaving dust, at Hazaribagh in the capital. The dry waste is ground and supplied to poultry feed mills or farmers

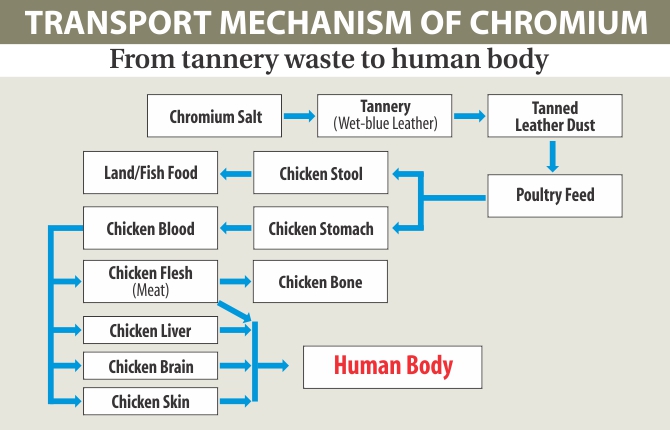

It's difficult to say exactly when it began. Records suggest the practice of making poultry-fish feed out of Hazaribagh tannery waste has been going on for over a decade. On December 30, 2003, The Daily Star reported that the feed, produced by crooked traders in the capital's Hazaribagh, contained chromium, a chemical used in tanning hides. The toxic feed consumed by fish or poultry enters the food chain and can damage liver and kidney, and cause cancer and other diseases, the report said.

The then state minister for fisheries and livestock, Ukil Abdus Sattar, told this newspaper he was unaware of such activities but he would look into it. Other officials concerned also admitted their ignorance and said they would take action.

Later, more media reports exposed the extent of feed contamination. The High Court on August 8, 2011, directed the government to stop the use of tannery waste in poultry feed as well as fish meals within 30 days.Yet the business kept flourishing. About a hundred factories in Hazaribagh now produce feed daily out of some 75 to 200 tonnes of solid waste that includes salt, bone, leather shavings and trimmings. Though the Rapid Action Battalion or the Department of Environment conducted one or two drives, things have hardly changed.

The Department of Livestock Services and the Department of Fisheries are entrusted with maintaining quality of animal feed. But they did not take effective steps. “I was not aware of the use of tannery waste in fish feed until recently,” fisheries department Director General Syed Arif Azad said, following a report in The Daily Star mid-July this year. He, however, said that in the last six months, the department tested over 1,200 fish feed samples from across the country and found shortage of protein in some samples.

The department warned the manufacturers but lodged no criminal cases. All it did was getting the manufacturers to apologise and pledge quality in future.

“Cases take so long … there are also certain procedures, you know,” Arif told this newspaper. The department also did not test heavy metals in the feed. However, Arif said they would do this now as the reports of animal feed being mixed with tannery-based protein are coming out.

The livestock department, however, filed one case and that is against Amir Multi-protein Ltd in Hazaribagh in March after a Rab-led drive found the factory was operating illegally. “There is no registered feed mill in Hazaribagh. However, if we have information about anyone manufacturing contaminated poultry feed, we can take action,” said Director General Mozammel Hoque Siddiquee of the livestock department.

Following The Daily Star report on July 15, the Rab led a drive and livestock department officials sealed off four illegal feed factories in Hazaribagh.

After the raid, the livestock department filed a criminal case against three illegal poultry feed factories.

Moshiur Rahman, president of Feed Industries Association of Bangladesh (FIAB), said they had notified the government of the alarming practices in 2007 and several times later.

“There were one or two drives but it took only some days for the illegal factories to restart. Who knows whether they bribe police?”

According to Moshiur, the FIAB members produce around 80 percent of the 30 lakh tonnes of feed a year. The image of the industry is being tarnished for the unscrupulous traders in Hazaribagh.

On February 10, 2011, the then Department of Environment director Munir Chowdhury seized toxic feed in a raid and sued the owners. The accused were arrested but they came out easily after filing an appeal. “We had to face threats from some quarters. They seemed very powerful,” Munir said when contacted recently.

Some workers engaged in boiling and sun-drying the tannery waste said police take Tk 100-200 for each burner used for boiling the solid waste.

"Whenever a burner is on, one has to bribe the cops," said a tannery worker in Hazaribagh during a recent visit by a reporter from this newspaper.

"There is an association [of feed manufacturers] that pays police on monthly basis. Police become strict whenever there is a mobile court drive but they loosen the grip later," he said. Police, as usual, deny the allegation.

“We have destroyed toxic feed from some factories. We would not have done it if we had taken bribe from the factories,” said Moinul Islam, officer-in-charge of Hazaribagh Police Station, referring to a July raid in Hazaribagh.

Al Amin, executive magistrate of the Rab, who led a mobile-court drive lately, said, “We can conduct raids. But monitoring these factories is basically the responsibility of livestock and fisheries departments. Without a robust role from them, shady activities at these factories cannot be uprooted.” Published:Daily Star, September 17, 2014A Deadly Luxury

Fine leather products from Bangladesh are admired in the luxury markets throughout the world. However, these leathers are manufactured in the fifth most polluted area of the world. Tens of thousands of workers have been slaving away in inhumane working conditions, amidst pollution that has been causing serious health hazards for the citizens. To know more about this unrevealed world of slavery and pollution.

It is a very small and one of the most neglected parts of Dhaka; not only neglected but also hated. Most people refuse to go there if not forced for their survival. However, this small and clumsy of part of Bangladesh's capital is one of the country's biggest source of foreign export. The place is called Hazaribagh. This 3.58 square kilometre area houses more than 350 tanneries, 95 percent of Bangladesh's tannery industry.

Far from being an industrial complex, Hazaribagh is nothing more than a giant slum of tanneries where more than 15,000 workers are slaving their lives away. These tanneries use lethal toxic chemicals to treat rawhides and throw the toxic wastes out in the open sewers and pits completely untreated. To make matters worse, Hazaribagh is the address of around 200,000 people who are also vulnerable to serious health hazards caused by these toxic wastes.

fter observing the entire area of Hazaribagh, it is quite evident that nobody is concerned about any laws. The whole area is full of small tannery sheds like this, which supply the wet blues to all the big industries. After using these toxic chemicals on an industrial scale, the wastes are thrown into open sewers which finally discharge these toxic wastes into one of Dhaka's lifeline-- the Buriganga River. Not a single tannery uses any treatment plant to remove the highly toxic substances such as acids and chromium before discharging the wastes. Md. Mizanur Rahman, the owner of Samota Leather Complex and the treasurer of Bangladesh Tanners Association says, “The Government has ordered us to relocate our factories to the under construction Savar Leather Industrial Park. In that 200 acre estate, a Common Effluent Treatment Plant (CETP) will be installed to refine all the wastewaters.”

In 1965 when the leather industry started to rise in Bangladesh (then East Pakistan), there were only 30 tanneries in the Hazaribagh area which was not a part of the capital at that time. Now the number has increased up to 350 and now Hazaribagh has become a densely populated residential area. However, residents of Hazaribagh are passing the days in misery. “I can still remember my first day at Hazaribagh. The smell was so disgusting that my wife and my 9 years old daughter started throwing up and then fainted. We all were sick for a whole month. I do not want to stay in this disgusting place, but I have no option,” says Asadullah, a bank employee and a resident of Hazaribagh.

ince the factories have been continuously discharging these carcinogenic chemicals untreated, the local residents and also the workers are highly vulnerable to fatal diseases like cancer and other health hazards.

There is no doubt that the tannery industry is one of the most important industries of Bangladesh. Exquisite leather products made by top quality leathers from Bangladesh are appreciated in the luxury marketplaces of Europe and North America. After readymade garments, the leather industry is the most prosperous in Bangladesh. It is also one of the very few, if not the only, industries for which we do not have to import raw materials.

However, the inhumane working condition and intense pollution has brought this industry to the centre of controversy. Recently, Human Rights Watch has published a detailed report on the working condition in Bangladeshi tanneries. Again, two renowned research organisations called Blacksmith Institute and Green Cross Switzerland has declared Hazaribagh the fifth most polluted area in the world.

There is no time to waste, there can be no excuse. Steps must be taken immediately to stop this form of slavery in the tannery industries and to force the factories to stop such pollution. Waiting for relocation cannot be an excuse to continue such exploitation of humans and environment alike, which is pushing hundreds and thousands of lives into the jaws of certain death (Daily Star, 9.10.15).Last Modified: October 9, 2015